Imagine holding a gilded page of an antique book in your hands, brush poised to reattach a fragile thread of binding. Your breath slows. One slip—a single bead of excess glue—and the flaw will outlive you. This is the moment when fingertips fail. When the tiniest miscalculation turns restoration into regret. Or picture a technician sealing a microsensor on a circuit board, only for adhesive seepage to short-circuit weeks of work. In both cases, the culprit isn’t skill—it’s control. Are we truly in command of every drop we dispense?

A Revolution in Eight Centimeters

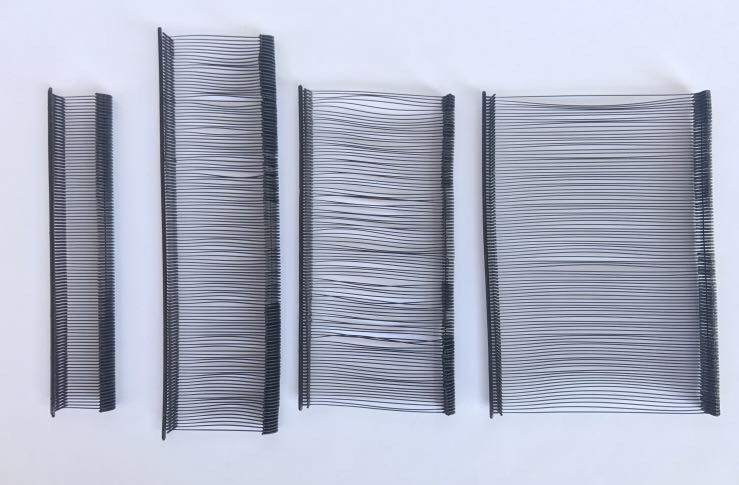

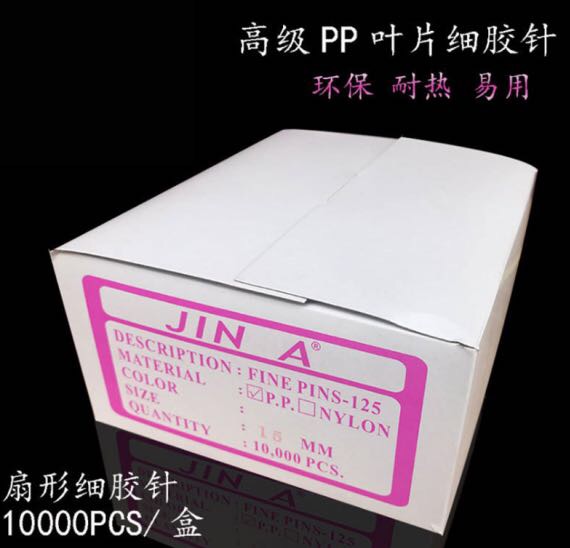

The 8cm Thin Glue Needle emerges not as a gadget, but as a recalibration of what precision means. At first glance, it resembles a surgeon’s instrument—slender, gleaming, almost delicate. Yet within its compact frame lies a rigid medical-grade stainless steel core engineered to withstand high-viscosity adhesives without clogging or bending. Unlike bulky glue guns that drip unpredictably or droppers that leave behind sticky trails, this needle delivers adhesive with surgical accuracy.

Traditional tools falter under pressure—literally. A trembling hand amplifies wobble in long nozzles; short tips limit visibility and leverage. The 8cm length isn’t arbitrary. After extensive fluid dynamics testing, engineers identified this span as the sweet spot: long enough to grant clear line-of-sight over complex surfaces, yet short enough to minimize deflection and maintain tactile feedback. It’s the golden ratio of control—where stability meets agility.

The Invisible Hero Across Worlds

This tool transcends categories. In the quiet studio of a rare book conservator, the needle traces along century-old spine threads, depositing microdots of pH-neutral adhesive exactly where needed—no more warping, no staining. For the glass artist crafting layered ornaments, it enables seamless edge bonding without fogging transparent joints. Even in electronics manufacturing, technicians use it to isolate moisture-prone components with pinpoint sealant application, avoiding costly rework.

What unites these diverse users? A need for invisibility—not just in results, but in process. The best tools don’t draw attention; they disappear into intent.

Ending Waste, One Microliter at a Time

Conventional methods can waste up to 40% of adhesive through drips, smears, and cleanup residue. Visualize half a bottle of specialty glue—precious, expensive—lost to imprecision. Now imagine cutting that waste by more than half. That’s the reality for jewelers using the 8cm Thin Glue Needle. One artisan reported reducing monthly adhesive costs by 60%, simply by eliminating over-application during stone setting.

Beyond savings, there’s philosophy: “less is more.” Less mess means less solvent use, fewer wipes, lower environmental footprint. Every precise dot applied is a small act of sustainability—an ethos embedded in design.

Engineered Obsession: Why Not Thinner? Why Not Shorter?

You might ask: why stop at 8cm? Why not go longer for reach, or thinner for finer lines? The answer lies in physics and persistence. Over 18 months, the development team tested 67 prototypes, analyzing flow rates, backpressure, and user fatigue. Too thin, and viscous glues jam. Too short, and hand tremors become catastrophic.

The final design balances three forces: needle diameter (0.6mm), taper angle (12°), and overall length. This triad creates laminar flow—smooth, consistent output—even with epoxy or cyanoacrylate. The stainless steel resists corrosion from aggressive solvents, while the ergonomic grip features micro-textured ridges that conform to finger curvature, reducing slippage during prolonged use.

When the Tool Vanishes, Mastery Emerges

True precision feels effortless. As you press the plunger, resistance builds slightly—just enough to signal engagement, never so much as to induce shake. The weight settles perfectly in the palm, balanced near the midpoint like a fine pen. With each use, the boundary between hand and instrument blurs. You’re no longer “using” a tool; you’re extending your will.

This is the “tool disappearance” principle: the highest form of craftsmanship aid doesn’t shout its presence. It listens, responds, and obeys—so quietly you forget it’s there.

Stitching the Future, Drop by Drop

As devices shrink and art grows bolder, the demand for microscopic control intensifies. Wearable tech assembly requires adhesives placed within fractions of a millimeter. Bio-artists embed living cells in resin matrices, needing color-stable, non-toxic bonding at cellular scales. These frontiers aren’t served by brute force—but by finesse.

The 8cm Thin Glue Needle is more than a solution for today. It’s a standard for tomorrow—one that may soon find its way from cleanrooms to kitchen drawers. Because when perfection hinges on a single drop, anything less than absolute control is simply… glue gone wrong.